Our manufacturing capabilities

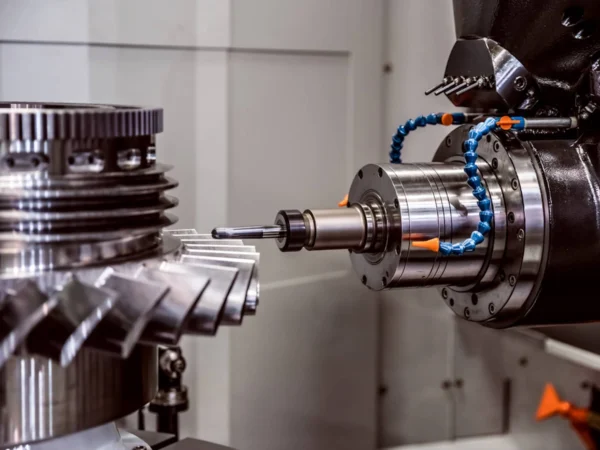

BestPro Precision Manufacturing Ltd provides high-quality prototyping,

low and large-volume manufacturing services to support your product development needs.

Our international team will work with you to make your product ideas a reality through

high-tech CNC equipment and ensure your parts are shipped on time.

We also specialize in sheet metal fabrication and Metal Injection Molding (MIM) technology.

Additionally, we provide comprehensive casting and forging services from raw materials to the final finished product. We use tried and tested suppliers but perform all in-house secondary machining and QC operations.

We're your source if you’re looking for the right machine shop in China!

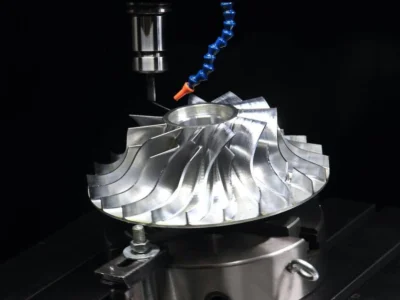

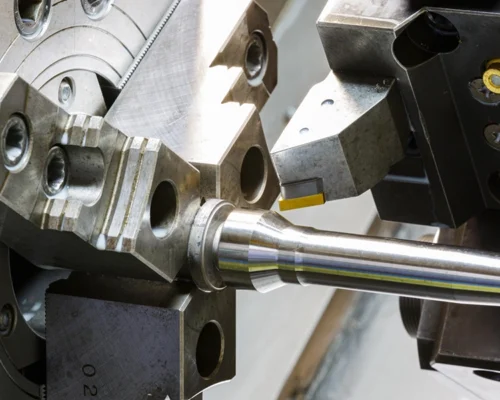

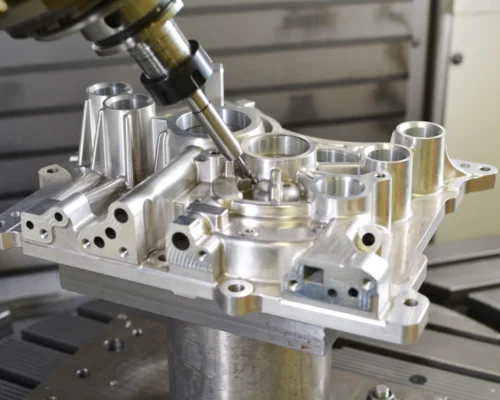

CNC Lathe, CNC Turning, 3 Axis CNC Milling, 4 Axis CNC Machining Center, 5 Axis CNC Machining Service

Casting

Die Casting, Sand Casting, Lost Wax Casting, Gravity Casting, Investment Casting

Forging

Open-Die Forging, Close-Die Forging, Press Forging, Hot Forging, Cold Forging

Sheet Metal

Laser Cutting, CNC Cutting, Stamping, Bending, Welding, Riveting, Stretching, Punching, Rolling/Forming

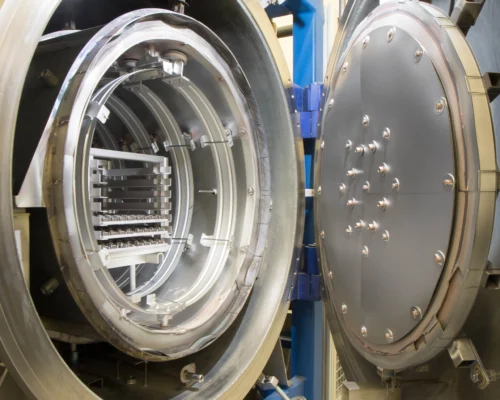

MIM&Sintered

Powder Preparation, Injection Molding, Debinding, Sintering/Burning, Post-Sintering

Finishes Service

Add multiple finishes to your parts, such as Anodizing, Sand Blast, Powder Coat, Plating, etc.

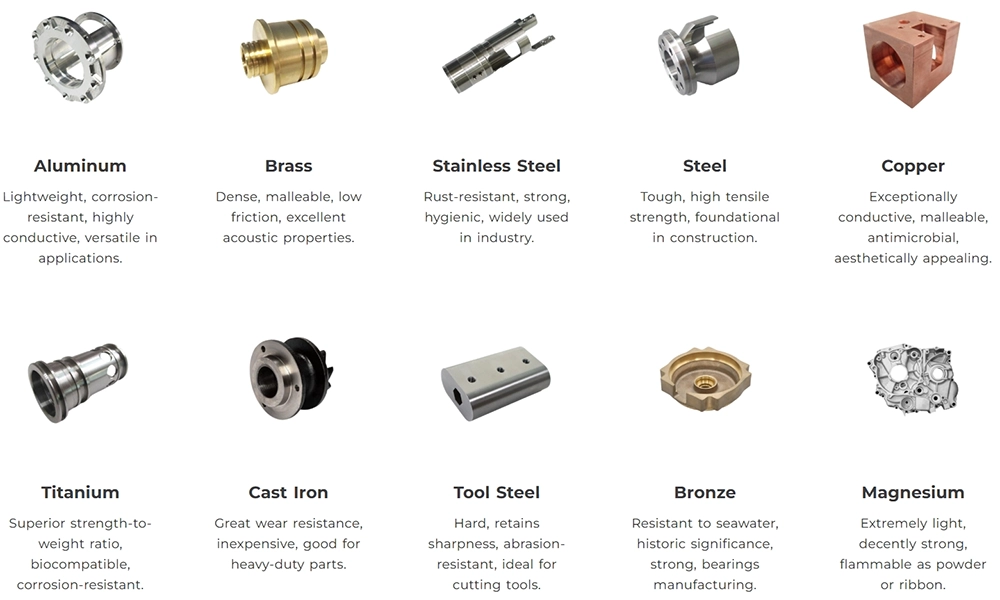

100+ Materials Can Be Freely Selected

Industries we serve

With 15 years of machining expertise under our belt, we’ve catered to a broad spectrum of sectors including medical, robotics, consumer goods, automotive, aerospace, defense, marine, green energy, and industrial, among others.

Our deep understanding of our clients’ diverse applications, industry norms, and unique requirements across these fields is what truly sets us apart and adds value for our customers!

Overview of BestPro's Machining

- Common materials

Aluminum Alloys, Stainless Steel, Carbon Steel, Alloy Steel, Titanium Alloys, Copper & Copper Alloys, Plastics - Surface Treatment

Hard Coating, Black Anodize, Clear Anodize, Hard Chrome, Clear Zinc, Plasma Nitride - Axis Travel

X*Z: 1000mm*3000mm - Dimensional tolerance

Generally ±0.1 mm to ±0.05 mm, our accuracy can be as high as ±0.005mm

- Common materials

Aluminum Alloys, Stainless Steel, Carbon Steel, Alloy Steel, Titanium Alloys, Copper & Copper Alloys, Plastics - Surface Treatment

Hard Coating, Black Anodize, Clear Anodize, Hard Chrome, Clear Zinc, Plasma Nitride - Axes Travel

X*Y*Z: 3000mm*2000mm*1000mm - Dimensional tolerance

Generally ±0.1 mm to ±0.05 mm, our accuracy can be as high as ±0.005mm

- Common materials

Aluminum Alloys, Stainless Steel, Carbon Steel, Alloy Steel, Titanium Alloys, Copper & Copper Alloys, Plastics - Surface Treatment

Hard Coating, Black Anodize, Clear Anodize, Hard Chrome, Clear Zinc, Plasma Nitride - Axes Travel

X*Y*Z: 1200mm*1400mm*1000mm - Dimensional tolerance

Generally ±0.1 mm to ±0.05 mm, our accuracy can be as high as ±0.005mm

- Processing Capabilities

Sand Casting, Die Casting, Investment Casting, lost wax Casting, Gravity Casting - Common materials

Cast Iron, Aluminum Alloys, Steel, Bronze, Copper - Dimensional tolerance

±0.2 mm to ±0.5 mm - Surface Treatment

Deburring, Polishing, Sandblasting, Electroplating, Coating, Heat Treatment, Descaling, Chemical Plating, Spray Coating

- Processing Capabilities

Hot Forging, Cold Forging, Open-die Forging, Closed-die Forging, Press Forging - Common materials

Steel, Aluminum Alloys, Titanium Alloys, Copper Alloys, Stainless Steel - Dimensional tolerance

±0.1 mm to ±0.5 mm - Surface Treatment

Deburring, Polishing, Sandblasting, Electroplating, Coating, Heat Treatment, Chemical Plating, Phosphating

- Processing Capabilities

Laser Cutting, CNC Cutting, Stamping, Bending, Shearing, Welding, Riveting, Punching, Rolling, Stretching - Material Thickness

0.5mm-20mm - Common materials

Carbon Steel, Stainless Steel, Alloy Steel, Aluminum, Copper & Copper Alloys, Galvanized Steel, Titanium, Nickel Alloys, Tool Steel - Maximum Processing Size

Laser Cutting: Typically handle sheets up to 1.5 m × 3 m.

Bending Machines: Typically handle lengths of up to 3 m or longer. - Dimensional tolerance

±0.1 mm to ±0.5 mm - Surface Treatment

Painting, sandblasting, electroplating, anodizing, galvanizing

- Processing Capabilities

Medium and high production volumes

Typical part weights from under 1 gram up to 40 grams - Common materials

Stainless steels, heat resistant and low alloy steels - Features

95-98 % of the theoretical density

Good surface finish - Dimensional tolerance

Tolerances typically +/- 0,3-0,5% - Machining Process

Preparing the Feedstock – Injection Molding – Debinding – Sintering

Why Choose BestPro?

Experienced Machining

Drawing from our expertise, we’ll scrutinize your part’s manufacturability, advising on materials and design optimizations to provide cost-reduction strategies tailored to your needs.

High Precision Accuracy

BestPro commitment to meticulous accuracy delivers parts that consistently meet the strictest specifications, ensuring your projects are executed flawlessly.

Quality Assurance

Our ISO 9001:2000 certified company guarantees quality through SGS certifications, material authenticity, and detailed inspection reports for our customer’s peace of mind.

Cost-Effective Solutions

Experience significant savings of 30-50% with us, thanks to our optimized production processes and stringent cost management, ensuring economical pricing without quality compromise.